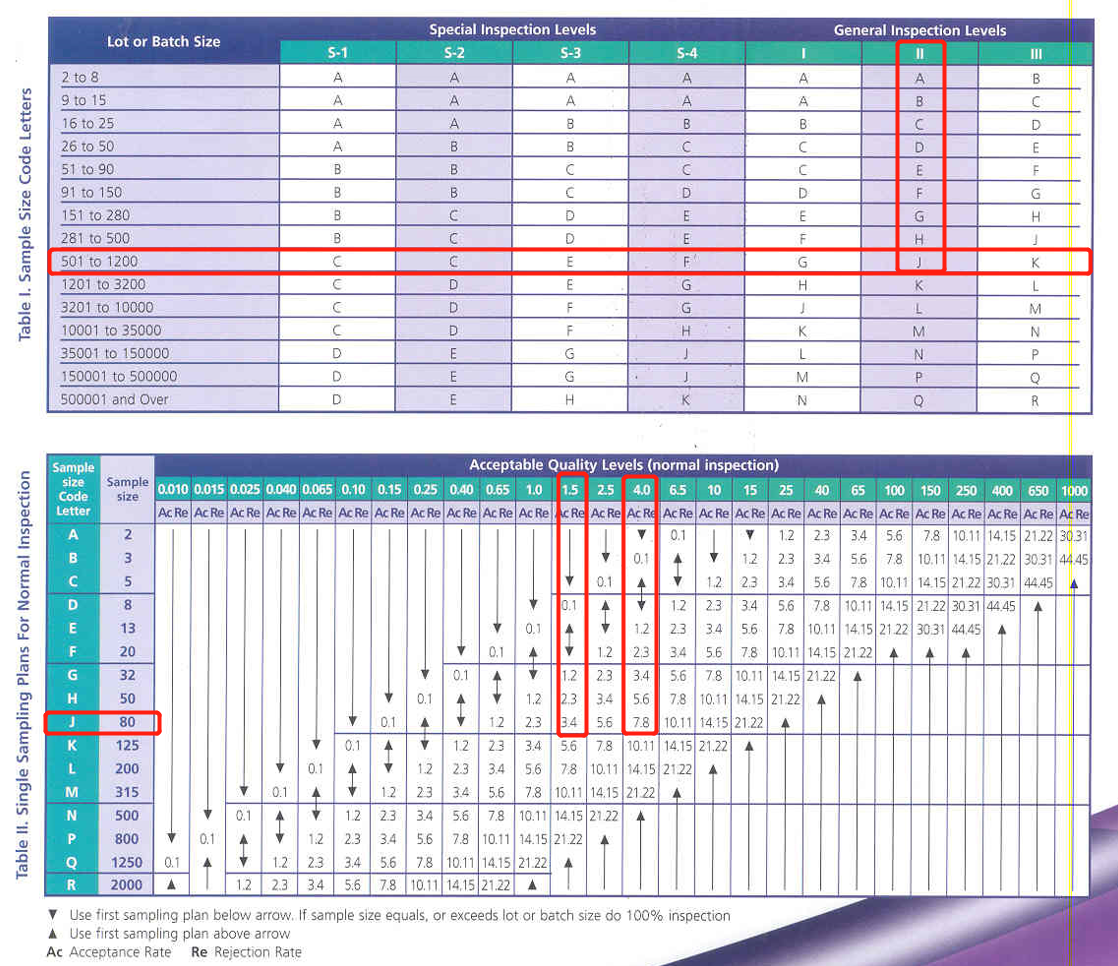

AQL table

AQL TABLE

Suggestion on AQL Levels

| Classification | High Valued Products | Low-medium Valued Products |

|---|---|---|

| Critical Defects | 0 | 0 |

| Major Defects | AQL1.0/1.5 | AQL2.5 |

| Minor Defects | AQL2.5/4.0 | AQL4.0 |

Understanding AQL

How do I determine the right sample size and acceptance number?

As an example, in an inspection of a 1,000 units lot, with an Acceptable Quality Level of II, up table A indicates that sample size code letter should be "J" . Table B indicates that the sampling size of "J" should be 80 units. For an AQL of Cri:0/Maj:1.5/Min:4.0, the corresponding acceptance number is Cri: 0/ Maj:3/Min:7. (the CRI defect not allowed, Maj defect acc Max 3, Min defect acc Max7)

It means the defective units not allowed over 0/3/7 pcs we found from 80pcs samples, if one of number over its, it should be rejected this lot.

What should I do with defective or discarded lots?

Defective items found as part of 100% inspection can be discarded, repaired or replaced. You may opt to buy the discarded lot at a discount for resale at a lower price.

Defects detected during visual inspections are classified into three categories as follows:

Critical Defect – corresponds to a defect likely to be unsafe for consumers. Our default Critical Defect AQL is Not Allowed.

Major Defect – results in function failures or reduction of product usability or obvious appearance faults which may affect the salability of the product sells. Our default Major Defect AQL is 1.5(for E-products)/2.5 (Non-E products).

Minor Defect – doesn't reduce the usability or function of the product, but is beyond the defined quality standard and may reduce the salability of the product. Our default Minor Defect AQL is 4.0.

Clients can also specify what points are Minor, Major or Critical in their own checklists.

Send Email

Send Email INMAXYCY

INMAXYCY